The big news in Australia’s joint strike fighter project in the past year was the arrival of the first two F-35s at RAAF Williamtown in December. Australian-owned aircraft have been operating for several years in the United States, but they’ve never been based here in Australia before.

The international picture is also positive. All three US services, each operating a different variant of the F-35, have declared initial operating capability. The US Marine Corps and Air Force have deployed squadrons overseas. US military leaders have testified that the JSF has achieved kill ratios of over 20 to 1 in exercises and completed missions that were well beyond the ability of fourth-generation aircraft.

It’s been a long journey, starting in Australia’s case with the government’s decision in 2002 to identify the JSF as the preferred future air combat capability. Along the way the program has overcome many hurdles, but there’s still a long way to go until Australia achieves full operational capability in late 2023.

Many military capabilities have entered service with their sustainment systems underdone, and it appears the F-35 will be no exception. In this regard, a report by the US Government Accountability Office makes for sobering reading. Like auditors worldwide, the GAO’s tend to be glass-half-empty people, but their analysis can’t simply be ignored.

The JSF program office is responsible for meeting the sustainment requirements of all participants in the multinational program, and Lockheed Martin is responsible for managing the supply chain. The global JSF support concept is essentially a military analogy of the modern Amazon-style just-in-time logistics concept that we’ve all become used to in our daily lives.

In principle, this approach has benefits. Why shoulder the cost of having a warehouse at Williamtown full of expensive spares like radars when the ADF may on average need only a handful each year? If you can get one at short notice whenever you need it from a warehouse in Guam or Belgium or Turkey, being part of a pooled approach saves money and makes financial sense.

But for it to make operational sense, the system has to work with the speed and reliability we have come to expect from Amazon and similar providers. And that’s where the JSF program is falling down.

The GAO highlights a number of areas in which major improvements are needed.

A fundamental area is simple management. Under the support concept, all spares in the global pool are owned by the US Department of Defense. But the state of the department’s logistics systems means that it doesn’t know what spares it needs, what spares it has, where the spares are, what individual spares cost, or what it is paying overall for sustainment. Despite one of the main selling points of the JSF being its autonomic logistics information system (ALIS), which promised to integrate mission planning, support and supply chain management, much of the JSF’s sustainment is still conducted through traditional, manual paperwork. It’s a far cry from Amazon.

At the moment, there’s no way for individual nations to get around this by stockpiling their own spares. The US Defense Department assigns spares to participants according to priority, and highest priority is given to units that are in combat or on operations. That makes sense, but even that is working far from perfectly. Packages of spares to support deployments have to be ordered two to three years in advance and, based on recent US Marine Corps deployments, 44% of the spares taken on deployment turned out to be incompatible with the aircraft they were meant to go on.

The target date for military depots to have the ability to repair parts has moved from 2016 to 2024. Until then, they need to go back to the original supplier for repair. Similarly, the distribution network to move parts between users around the world also won’t be fully up and running until 2024.

What does this mean in terms of capability? The F-35A, which Australia is acquiring, is the best performing of the jet’s three variants. But it’s still not great. From May to November 2018, the F-35A achieved a 47% air vehicle availability rate, a metric ‘that measures the percentage of time during which aircraft are safe to fly, available for use by units, and able to perform at least one tasked mission’.

But it has only achieved a 34% full mission capable rate, which measures the percentage of time that aircraft with units ‘are fully capable of accomplishing all tasked missions’. The targets for the two metrics are 75% and 60%, respectively. While parts shortages aren’t the only reason aircraft are unable to fly, it’s the reason 30% of the time. The target is 10%.

Incidentally, for those (like me) who think that Australia should acquire at least some F-35Bs (the short take-off and vertical landing variant), note that they have only achieved a 16% full mission capable rate. (Although that hasn’t stopped the US Marines from declaring initial operating capability.)

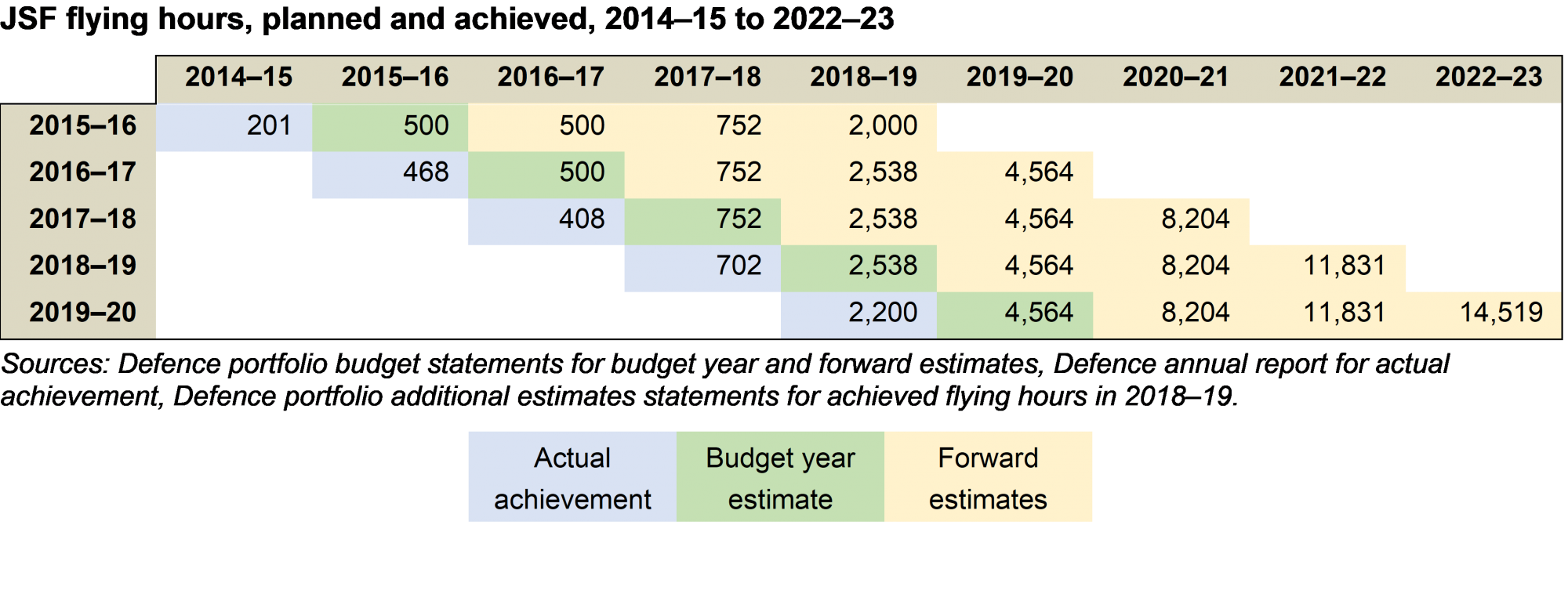

What does this mean for Australia? The table below presents the increase in flying hours in Australia’s program. Each year to date, the program has fallen short of the target. That’s typical for new capabilities being introduced into service, and it hasn’t necessarily been by much, so that’s not too worrying. But on the steep ramp up to full operational capability, there will need to be a sixfold increase over the four years from 2018–19 to 2022–23.

With Defence pumping nearly $2.5 billion a year (page 109) into acquisition of aircraft, it seems likely it will get its 72 F-35As on schedule. But if it has to compete with militaries across the world for spares provided by a supply chain that’s still a long way from functioning like a well-oiled machine, it seems reasonable to ask whether the air force will be able to fly those aircraft as much as necessary to convert pilots en masse from the Hornet.

With Defence pumping nearly $2.5 billion a year (page 109) into acquisition of aircraft, it seems likely it will get its 72 F-35As on schedule. But if it has to compete with militaries across the world for spares provided by a supply chain that’s still a long way from functioning like a well-oiled machine, it seems reasonable to ask whether the air force will be able to fly those aircraft as much as necessary to convert pilots en masse from the Hornet.

If the supply chain and ALIS aren’t working well in peacetime, they’ll have to get a lot better to be robust enough to function in wartime. Not only will they become a prime target for cyberattacks, but consumption of spares will soar, putting greater pressure on the system. If the US, by far the biggest consortium member, is fighting a war, spares for our air force could become very sparse indeed.