With the global semiconductor supply chain under strain, India and Australia have a timely opportunity to strengthen their partnership in the critical sector. Both recognise the strategic importance of developing domestic semiconductor capabilities. As Quad members, they are also a part of the Quad Semiconductor Supply Chain Initiative, which seeks to ‘map capacity, identify vulnerabilities, and bolster supply-chain security for semiconductors and their vital components.’

To take this agenda forward, this article proposes five practical ideas for bilateral cooperation. We have intentionally omitted ideas that require high capital investment and collaboration effort.

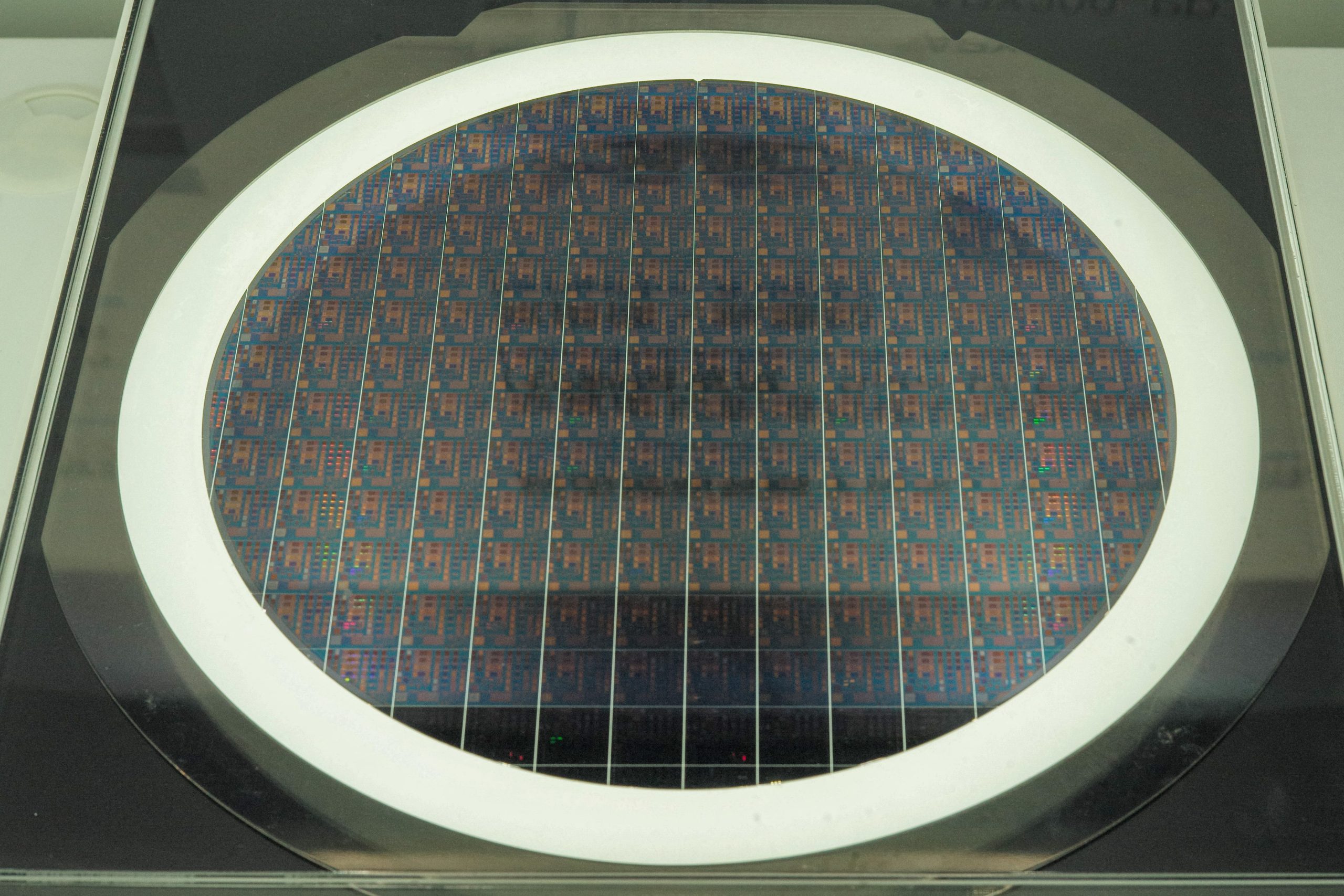

First, joint commercial projects offer a pragmatic starting point. The Australian Space Agency’s International Space Investment India Projects program offers grants for partnerships between Australian and Indian space companies. Launched in 2023, the program comprises funding of $20.69 million over four years. A similar design initiative for semiconductors, including in such emerging areas as chiplets (tiny specialised chips), would harness complementary strengths.

India has significant semiconductor talent, including nearly 20 percent of the world’s design engineers working in product and service companies. Australia has globally renowned research institutions known for their expertise such fields as quantum technologies; it also has a record of leadership in wireless communication and photonics. Grants for establishing collaborative chip design centres in Australia, where a large proportion of companies develop systems based on off–the–shelf technologies, would help spark new product development and help create a critical mass of talent on both sides.

Second, research collaboration will build a talent pipeline for the future. Australian universities are expanding their presence in India after regulatory changes in higher education there allowed local establishment of foreign campuses. Taking advantage of this, a dedicated India-Australia research academy focused on very large-scale integration design and new semiconductor materials could help drive innovation. This would leverage India’s software prowess and Australia’s expertise in advanced materials and could uncover new opportunities in areas such as packaging and compound semiconductors. The existing Indian Institute of Technology Monash Research Academy provides a model for bilateral PhD programs and student exchanges.

Third, access to each other’s R&D infrastructure would aid rapid prototyping in both countries for companies that lack fabs. India’s Semiconductor Laboratory and the Indian Institute of Science have research-focused semiconductor fabrication facilities, while Australia has developed open infrastructure facilities at the Australian National Fabrication Facility. Providing engineers reciprocal access to these facilities for prototyping and training would act as a catalyst.

Fourth, partnerships in outsourced assembly and test (OSAT) would support complementary initiatives and investment in either country. India is attracting investments from leading semiconductor firms for OSAT facilities (which provide third-party integrated-circuit packaging and test services). The New South Wales government in Australia aims to establish low-volume advanced packaging development infrastructure. Given the difference in their starting points, a partnership in this domain could enable seamless transfer of technologies requiring higher volume manufacturing capability. Another area for OSAT collaboration could be to offering training programs at new facilities for partner country engineers.

Finally, facilitating talent mobility through preferential visas will be vital. As India develops as a global semiconductor hub, a silicon visa scheme, similar to Australia’s Global Talent Independent program, could enable Indian engineers to work in the Australian industry for extended periods. Australia’s massive expertise in advanced materials could aid India’s push for advanced manufacturing. Young researchers and entrepreneurs would especially gain from bilateral exchanges.

We believe these five items are actionable without requiring significant investment or intra-government coordination. For some, templates already exist in other areas of cooperation. If these initiatives show promise, the two governments can collaborate on more complex areas, such as jointly funding a compound semiconductor fab, strengthening the global open-source hardware ecosystem, and signing patent protection treaties to enable joint silicon intellectual-property ownership.

With concerted efforts towards building commercial linkages, research collaboration, and talent mobility, India and Australia can put their partnership to work in strengthening domestic semiconductor capabilities. Their complementary strengths and shared interests position them well to collaborate across the semiconductor value chain, from materials to design, manufacturing and advanced packaging.