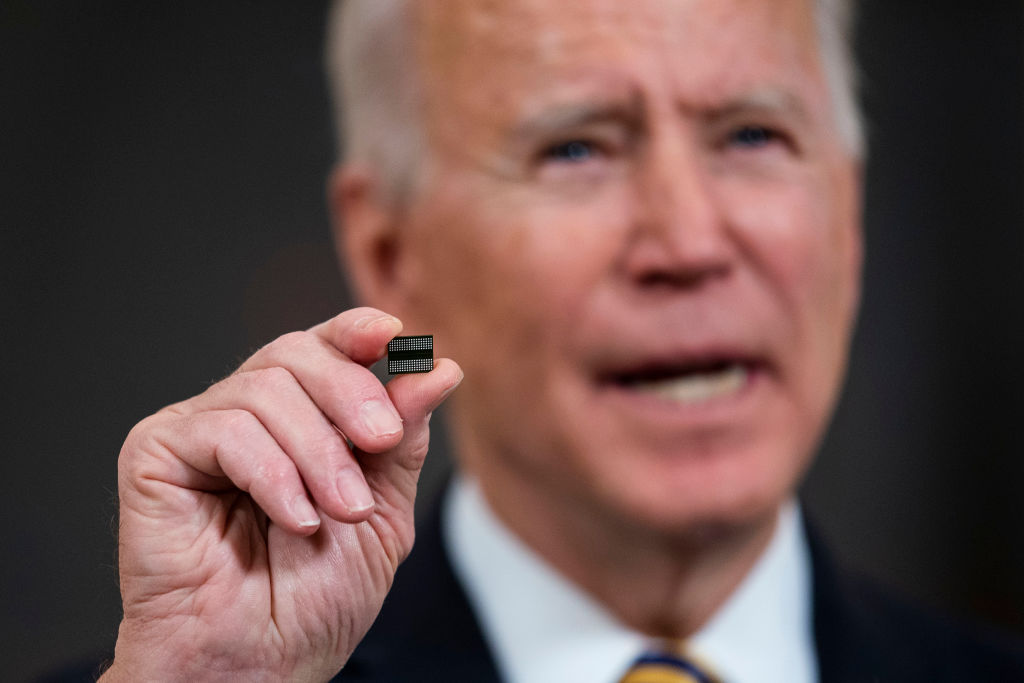

In August, the US government made a major commitment to America’s semiconductor manufacturing sector with the announcement of US$50 billion in funding under the CHIPS and Science Act. Bolstered by this move, memory chip manufacturer Micron announced a US$40 billion investment with the potential to create 40,000 new jobs in construction and manufacturing.

But it turns out the CHIPS Act was just the start.

On 7 October, the US Commerce Department announced sweeping export controls on ‘advanced computing integrated circuits (ICs), computer commodities that contain such ICs, and certain semiconductor manufacturing items’. In addition, the Bureau of Industry and Security has added 31 Chinese institutions and corporations to its unverified list because of ‘sustained lack of cooperation by a foreign government that prevents BIS from verifying the bona fides of companies’. The restrictions apply to all US citizens who support the development or production of chips in semiconductor fabrication plants in China without a licence.

Historically, the US had the lion’s share of the global semiconductor industry (37% in 1990), but its dominance has been eroded by North Asian markets over the past three decades. In 2020, Taiwan (22%), South Korea (21%), Japan (15%) and China (15%) accounted for 73% of global semiconductor manufacturing, compared with the US’s 12%.

The Semiconductor Industry Association, which represents 99% of the US semiconductor industry, projected in its 2020 report that the US share of the market would decline to 10% by 2030, while China would boost its share to nearly a quarter (24%), closely followed by Taiwan (21%) and South Korea (19%). The report emphasised the difference between the minimal amount of US government support provided to semiconductor companies compared to most Asian countries and made a series of recommendations. Semiconductor manufacturing in China, for example, is intensely supported by government policies under the ‘Made in China 2025’ plan.

Semiconductors have become ubiquitous in many aspects of our daily lives and are important for other critical technologies such as artificial intelligence and quantum computing. Increased demand for semiconductor chips for cars, infotainment and other commodities, together with supply-chain issues driven by the Covid-19 pandemic, have led to a worldwide shortage. Memory chips have become an important share of the semiconductor manufacturing industry and sales of these devices have grown by 31% in the past three years.

The US might not hold the largest global share of semiconductor manufacturing, but it’s home to a number of critical semiconductor processing suppliers—namely, Applied Materials, KLA and Lam Research—and the export controls include services.

Most semiconductor fabrication facilities would be operating around the clock with a maintenance and service contract secured from these companies to address any faults or need for servicing in a timely manner to maximise operations and production. Service contracts are critical for most semiconductor fabrication facilities, and the restrictions introduced through the new export controls will severely affect both China’s semiconductor fabrication capabilities and, in the short term, US semiconductor processing companies like Lam Research and Applied Materials for which service contracts are a regular source of income. Applied Materials has estimated that it will make a US$400 million loss just from the announcement as US semiconductor tech companies grapple with the changes to their customer base and the rapid exit of all their staff from China.

In 2020, the Boston Consulting Group estimated that US companies could potentially lose 37% of their revenue if they were banned from selling to Chinese customers, which would affect the amount of investment in research and development and the availability of highly skilled jobs in the US semiconductor industry.

The impacts of the US export controls will go far beyond the sudden exit of traditional semiconductor companies from China. The semiconductor ecosystem is intertwined with other manufacturing sectors, such as companies that provide stainless-steel components, vacuum systems and parts (for example, US-based Varian and Swagelok) or metrology tools such as microscopes. Every company working in this broader semiconductor ecosystem will be taking stock of the repercussions.

Perhaps the greatest impact will be felt in the global 3D NAND semiconductor manufacturing sector. The 3D NAND flash memory is a technology first unveiled in 2013 by Samsung Electronics, which introduced a method of scaling the memory size by stacking several 2D NAND planar layers to form nano skyscrapers. The US controls apply to 3D NAND chips of 128 layers or more, which are fabricated through a high-precision process with more than 1,000 consecutive processing steps that require the continuous operation of a set of semiconductor processing workhorses.

The non-volatile memory industry has been revolutionised this year with the announcement first by Micron of a revolutionary 232-layer 3D NAND memory chip and then by SK Hynix of a 238-layer 4D NAND memory chip.

In August, China-based Yangtze Memory Technologies (YMTC), a newcomer to this field in 2018, threatened the oligopoly of the 3D NAND markets by announcing its own 232-layer 3D NAND product. YMTC is one of the companies expected to be severely impacted by the US government’s restrictions.

US companies like Micron will benefit from the export controls and the expected slowdown of YMTC’s rapid ascension in this competitive market. Shortly after the latest US announcements, ASML, a Dutch state-of-the-art lithography company that has a monopoly on deep UV lithography systems, put a hold on all its exports to China. Under the US ban, Applied Materials, KLA, Lam Research and ASML can no longer supply YMTC and other Chinese semiconductor companies. This will also mean that the processing and manufacturing equipment acquired from the US companies can’t be serviced for smooth operation. Under the same restrictions, US-based companies will be allowed to supply to semiconductor chip manufacturers like Samsung, SK Hynix and TSMC that have semiconductor fabrication facilities in China for one year.

It is not just businesses that are finding themselves at the pointy end of the decoupling. Universities are an important part of the R&D ecosystem for semiconductor research and there are currently close international collaborations between China and other countries in this area. The US restrictions will change the semiconductor research collaboration landscape with China in a similar way to the effects US export controls have had on research collaboration with Iran in recent years.